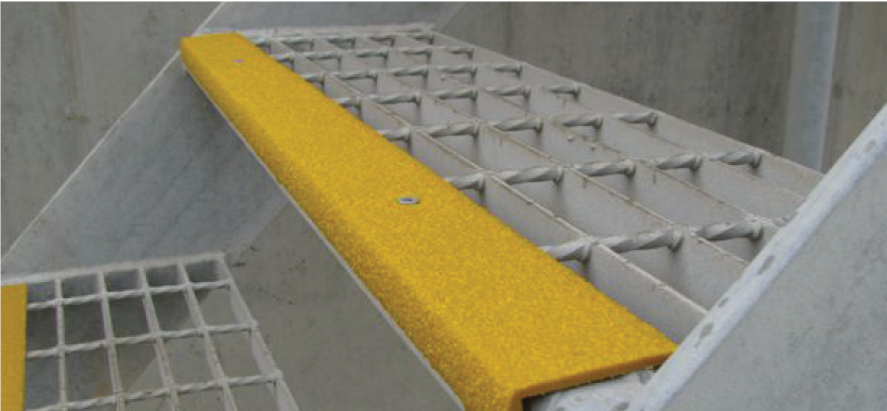

StairSAFE®- FRP Stair Nosing

Featuring robust fibreglass FRP construction, StairSAFE® stair nosing is designed to withstand the most severe environments. Our grid surfaces are impregnated into the substrate, ensuring that the possibility of delamination is reduced drastically. This also allows StairSAFE® to show remarkable chemical resistance, making it ideal for corrosive conditions.

Incorporated heavy duty grit surfaces provide a guarantee against any delamination which is a common issue with insecure metal backed alternatives. Further, fire retardant additives are infused to ensure excellent fire and heat resistance, conforming to ASTM E84.

With a product that lasts up to five* times as long as metallic alternatives, StairSAFE® FRP stair nosing not saves in terms of initial product cost, but also in reduced installation and maintenance time and cost.

Conforms to AS/NZS 4586, BS 7976-2202 + AI:2013, BS 8300: 2009 + AL:2010

*Statistics based on in-situ tests carried out on StairSAFE FRP nosing products in an ammonia production facility in Australia

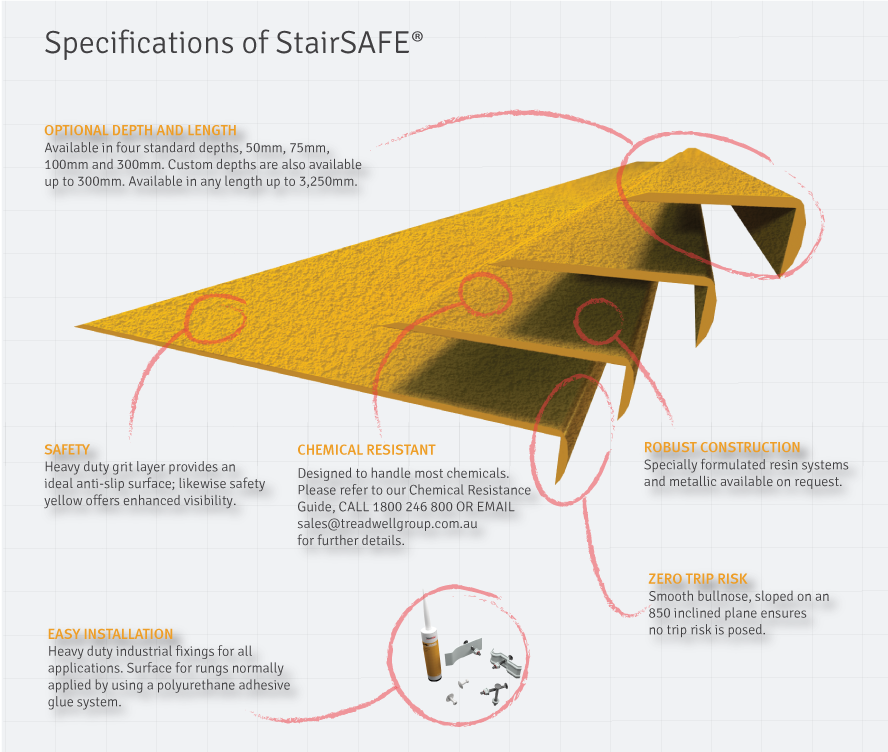

Specifications of StairSAFE™

OPTIONAL DEPTH AND LENGTH

Available in four standard depths, 50mm, 75mm, 100mm and 300mm. Custom depths are also available up to 300mm. Available in any length up to 3,250mm.

SAFETY

Heavy duty grit layer provides an ideal anti-slip surface; likewise safety yellow offers enhanced visibility.

CHEMICAL RESISTANT

Designed to handle most chemicals. Please refer to our Chemical Resistance Guide, CALL 1800 246 800 OR EMAIL sales@treadwellgroup.com.au for further details.

ROBUST CONSTRUCTION

Specially formulated resin systems and metallic available on request.

ZERO TRIP RISK

Smooth bullnose, sloped on an 850 inclined plane ensures no trip risk is posed.

EASY INSTALLATION

Heavy duty industrial fixings for all applications. Surface for rungs normally applied by using a polyurethane adhesive glue system.