Advantages of FRP Composites

Environmental Advantages of FRP Composites

Fiber reinforced polymer (FRP) composites are promoted as the new aged material of the 21st century because of its superior corrosion resistance, excellent thermo-mechanical properties, and high strength-to-weight ratio. The benefits of FRP composites can be realised from these physical characteristics and their potential in developing structural systems with service lives exceeding traditional materials.

Benefits1 include:

- Light weight, hence resulting in lower construction costs and increased speed of construction resulting in reduced environmental impacts.

- FRP composite materials’ high strength and stiffness characteristics can require less material to achieve similar performance as traditional materials resulting in minimising resource use and waste production.

- Potential to extend the service life of existing structures and to develop new structures that are far more resistant to the effects of aging, weathering, and degradation in severe environments.

- FRP composite products are highly resistant to rot and corrosion, present a longer and more economical service life and require less frequent energy-intensive maintenance and replacement. These fundamental advantages accrue to the remarkable overall sustainability characteristic of our FRP products.

Recycling Advantage of FRP Products

Where we are at this stage of technology, FRP can be recycled, though not currently economically viable on a large scale. There must be potential applications in which components generated from recycled fibres can be used to allow the energy spent to be viable.

Different recycling techniques can develop many different components, paving the way for many different recycling avenues. Products can be produced using recyclate material generated on grinding the composite, prepregnated waste from cut offs when manufacturing components to specific dimensions. Individual components such as fibres and fillers from thermal or chemical removal can be recycled back into components.2

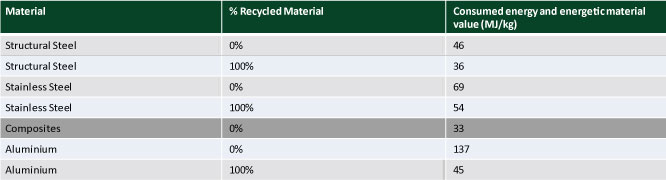

Nonetheless, based on research on applications conducted, we see that the production of FRP components consumes less energy and produces less greenhouse effect verses recycling steel and aluminum. For instance, a study in Rotterdam in 2003 3 compared energetic values of various material options in the construction of a pedestrian bridge and yielded the results below. Clearly composites present lower energy consumption.

1 Lee, L.S. & Jain, 2009, The role of FRP composites in a sustainable world

2 School of Metallurgy and Materials, University of Birmingham. 2010. The Reuse and Recycling of Glass Fibre Waste. Available at: http://etheses.bham.ac.uk/1342/1/Wait11MRes_A1b.pdf, viewed November 2016

3 Daniel, Ryszard A., Environmental Considerations to Structural Material Selection for a Bridge. European Bridge Engineering Conference, Rotterdam, March 2003.