GridEX® Pultruded FRP Grating

Treadwell’s GridEX® pultruded FRP grating systems are designed for specific applications where a standard fibreglass grating system cannot be effectively utilised. GridEX® offers you options such as selection of open space, bar shape, cross-rod placement, custom fabrication, custom resin or colour. The traditional “I” bar shape provides maximum flexibility in design. The “T” bar shape brings a more solid walking surface and prevents objects catching between load bars. The bar type profile is designed to take heavy wheel traffic such as fork lifts, tow motors and truck traffic.

The composite used in GridEX® pultruded FRP grating is around 75% lighter than steel and only 35% of the weight of aluminium which considerably simplifies installation and handling. Unlike metal grating, GridEX® grating can be easily cut on site using only hand tools, and no ‘hot-work’ tools such as torches or grinders.

Most common GridEX® options are available in 25 mm, 38 mm and 50 mm depths.

GridEX®

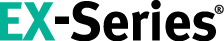

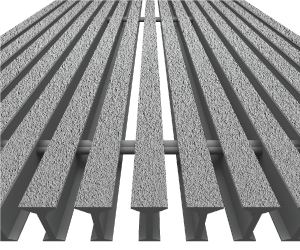

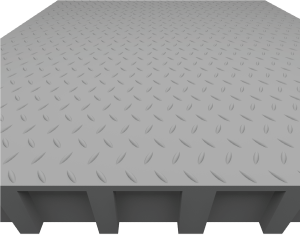

GridEX® Surface Options

Anti-Slip Surface A very hard-wearing surface with an extreamly good coefficient of friction (NATA laboratory test report available) - commonly used in industrial applications. Unlike serrated steel grating, the anti-sleep surface does not impact on load carrying capacity.

Ribbed Surface This non-stock option is very often utilised for appplications where high strength covered floors are required. The system is supplied with Checkerplate or Anti-Slip surface bonded to every load bar to ensure performance is maintained in harsh environments.

Covered Surface This is the preferred surface for environments where by-products are commonly caught by serrations, and is hence very often utilised in the food industry. This surface option can also be utilised for wet areas and wash down applications.